Gone are those days when products worked in silos. We are in the middle of Industry 4.0, which is all about connected devices that communicate with each other and allow seamless data exchange between them.

This digital transformation is also bringing a change in the embedded OEM market. Companies are now building smart, data-driven products that focus more on experiences and outcomes than functionality.

According to research, the embedded system market is expected to reach $116.2 billion by 2025. There has been a steady rise in demand due to various factors such as demand for advanced driver-assistance systems (ADAS) in hybrid vehicles, wearable devices, and the need for new components such as advanced medical equipment. In fact, digital transformation could become the key differentiator and generate alternate revenue for enterprises.

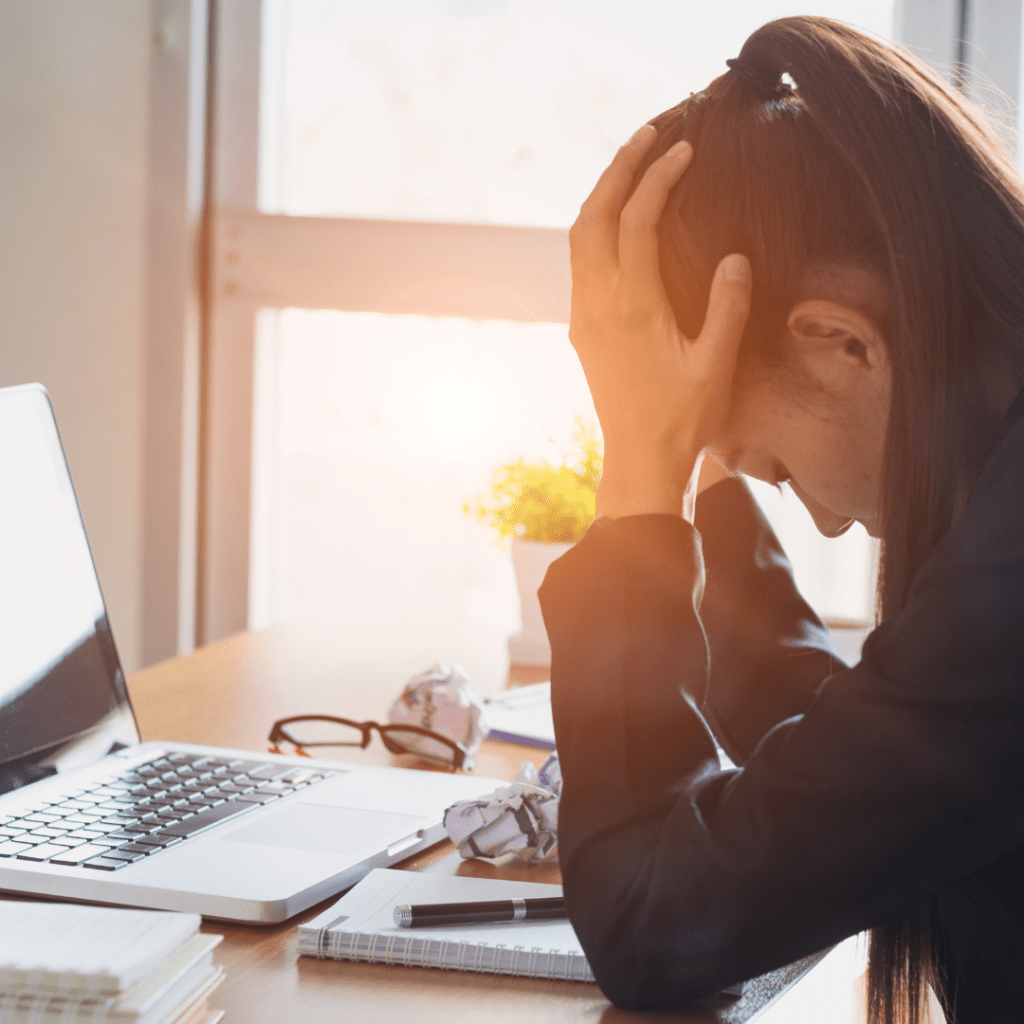

However, all of this will not generate an attractive valuation if Product OEMs fail to do the one critical thing – product documentation.

Why is Product Documentation Critical?

Traditionally, product documentation was always given the least priority in enterprises. They always depended on the experienced employees to pass on the knowledge verbally to the new ones. However, the gap between the baby boomers and millennials is increasing. It’s hard for enterprises to find the right replacement for the employees who are on the verge of retirement. By the time the role is filled, the older employee would have retired. So, there’s no documented process that could guide the new employees. There’s a disconnect between what the new employee learns and implements.

This disconnect could lead to various challenges:

- The enterprise will not be able to protect its intellectual property (IP).

- Many industry certifications require the enterprises to have their processes documented. Without documentation, the enterprise may fail to get certified.

- Lack of proper documentation could also result in the inability to comply with mandatory regulations.

- The enterprise also runs the risk of facing due diligence challenges during acquisition and mergers.

All these issues also make it challenging for the enterprise to implement product updates and adapt to the dynamic changes in the market.

What Should Enterprises Do?

Given the importance of documentation, enterprises need to prioritize it and make it a part of their development process. It will help the existing and new teams to avoid any hiccups during digital transformation or future updates.

Typically, the product documentation goes through a set workflow of requirement analysis, planning, designing, and maintenance.

- Requirement Analysis: The first step is to determine the target group. This will help in deciding the depth of the content to be documented. Work with the stakeholders of all the departments to understand the product in-depth and to ensure there are no assumptions or gaps in understanding.

- Planning: Plan the rough structure of the documentation to ensure that it is compliant with the legal standards and aligned with the enterprise’s brand guidelines.

- Design: The actual documentation and designing take place in this phase. The documentation is reviewed by the stakeholders to validate the content’s accuracy and completeness. The document is finalized once everyone has approved the content and design.

- Maintenance: Product documentation is a continuous process. In the maintenance phase, the documentation must be updated parallel to the product updates. This will help the existing and new team members get a complete understanding of the product and stay updated.

How Intellore Can Help with Product Documentation?

Intellore has a team of embedded product experts with rich domain expertise across various industries such as automation, transportation, etc. We have end-to-end experience in embedded product development, which includes concept development, requirements, design, development, verification, etc. Hence, we understand the significance of product documentation really well.

We follow a three-step approach to product documentation:

- Gap analysis: In this stage, we assess the existing documentation and compare it with the product to check if there are any gaps. We do a process maturity assessment and document our observations to create an implementation roadmap.

- Implementation: In this stage, we reverse engineer the products to understand them thoroughly and to fill the gaps. We understand the correlation between the different components and document accordingly. We implement the documentation along with appropriate workflows to make ensure that the documentation goes through the required reviews and approvals.

- Product Evolution: We understand that OEMs have to upgrade their products constantly. So, we update the documentation accordingly. We also create a workflow-driven framework to keep the documentation updated. The framework comprises best practices and easy-to-use templates to maintain the documentation.

Does this sound interesting? For more information, contact us.